Air and Gas Treatment

Discover Shanti Carbons’ advanced solutions for Air and Gas Treatment. Our Vapor Phase Carbon Adsorption Systems target specific gaseous contaminants, ensuring clean air in urban environments. With high-performance activated carbon technology, we combat volatile organic compounds (VOCs) and odors, meeting stringent air quality regulations. From trace impurity removal to odor control in various applications like car cabins and industrial facilities, our products offer versatile solutions. Partner with us to create a cleaner, healthier environment.

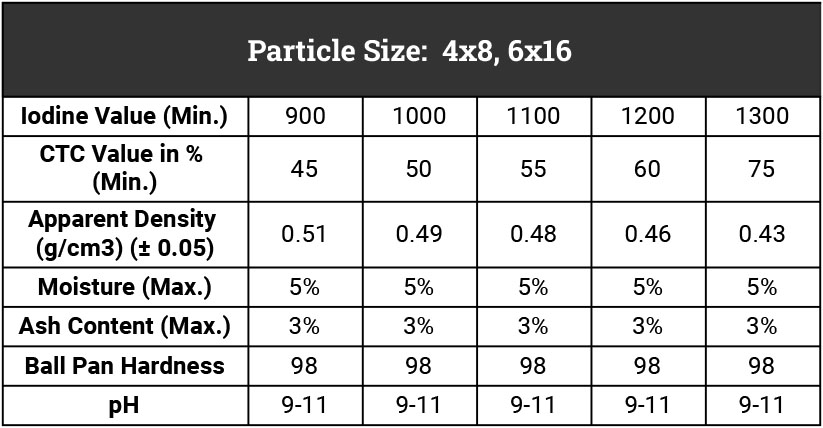

SC-SORB Series

Note: Custom mesh sizes tailored to your specifications are also available upon request.

Specialized Solutions and Services

- We identify the Activated Carbon Solution for your specific purpose and then provide iodine value, CTC, size, moisture etc. according to the need of that application.

- We provide Non-Washed, Water-Washed, Acid-Washed, Impregnated-grade (KI, KOH, TEDA, Cu, CuO, Ag etc), Surface Area Modification Activated Carbon Solutions.

- You have the option for both standard and customized packaging, including the ability to incorporate your branding onto the bags through printing support.

- Our products adhere to certification requirements for various applications such as ISO, NSF, HALAL etc.

Packaging and Shipping

- 25kg and 50kg laminated PP bags with inner liner or multi-walled kraft paper sacks, tailored to client specifications.

- For exports, 500kg Jumbo bags (super sacks) are palletized and shrink wrapped.

- Additionally, 25kg and 50kg bags can be palletized and shrink wrapped for export purposes.

- Instant Sample Delivery also available.

FAQ

Activated carbon, also known as activated charcoal, is a highly porous form of carbon with a large surface area. It is produced by heating carbonaceous materials such as coconut shells, wood, or coal to high temperatures in the absence of air, followed by chemical or steam activation. This process creates a network of pores that can adsorb various substances.

Activated carbon is widely used in various industries and applications including water treatment, air purification, gas and vapor phase filtration, chemical purification, wastewater treatment, food and beverage processing, pharmaceuticals, and environmental remediation.

When selecting activated carbon, consider factors such as pore size distribution, surface area, hardness, ash content, and the specific application requirements. It’s crucial to choose the right type of activated carbon to ensure optimal performance and efficiency.

In order to maintain cost efficiency for all parties involved, our minimum purchase quantity is 2 ton.

Sure thing! When you get in touch, it’s like finding a special treasure for us. We’re excited to work with you, no matter how small your order is. Let’s work together and grow in the future!

Yes, activated carbon can be recycled and reused in certain applications after regeneration. Regenerated activated carbon can maintain its adsorption capacity and effectiveness, reducing the need for disposal and contributing to sustainability efforts.